Research Stories

Bio-Oil Upgrading: using supercritical fluid to produce electricity and biofuels for next generation

Bio Oil upgrading supplementing drawbacks of fast pyrolysis.

Mechanical Engineering

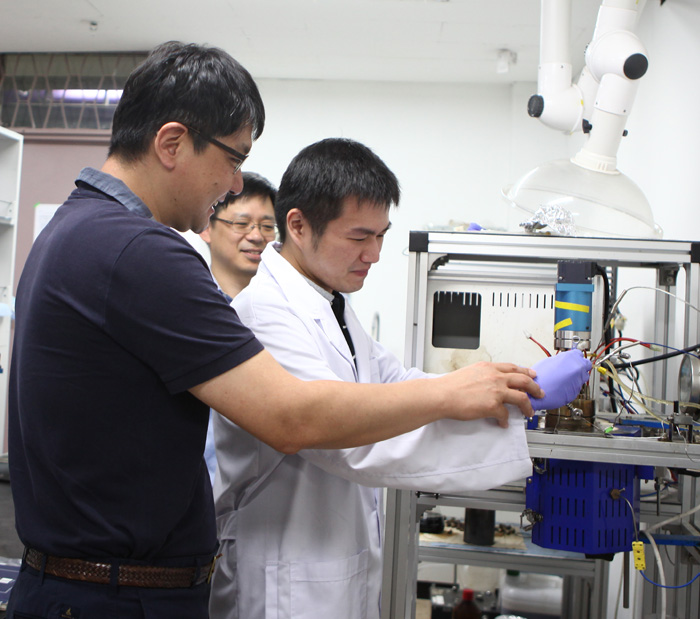

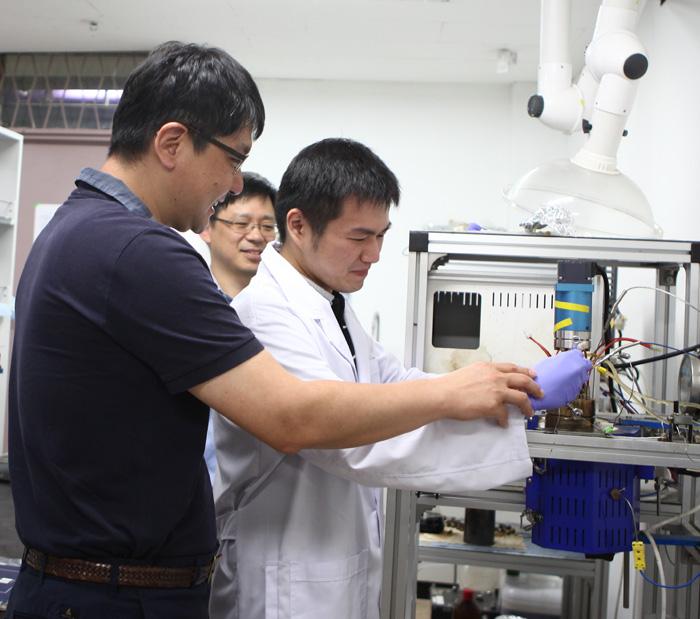

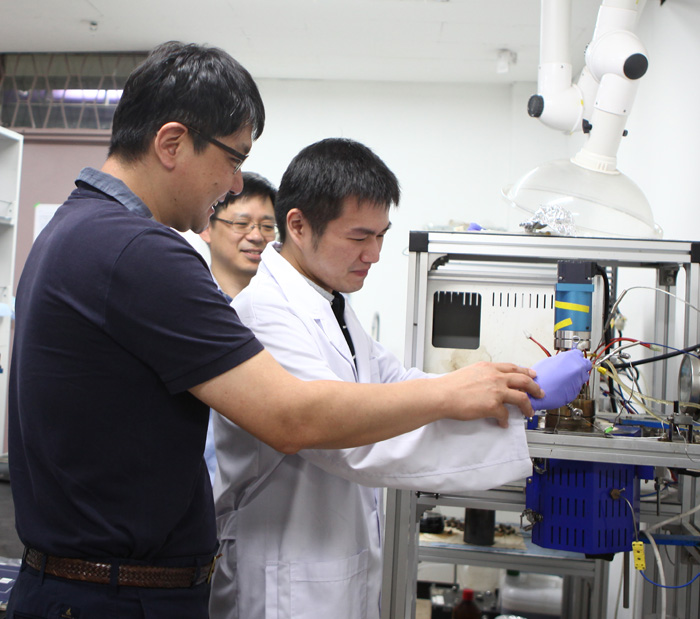

Prof.

KIM, JAEHOON

Among various heat transfer processes for biomass that are not dealing with food resources, “fast pyrolysis” is the most famous one. This process is derived from empty palm fruit bunch, which decomposes the material for a few seconds at the temperature of 400-600°C in an oxygen free environment, which produces liquid bio-oil. However, this process has many weaknesses like; (1) low heat stability and short storage period, (2) low energy content, (3) an instability to combine with fossil fuels, (4) low pH causing corrosion of machines, (5) separation of materials if stored for a long time.

Due to these weaknesses, bio-oil is not easy materials to transfer, store, and use. This research is about bio upgrading and eliminating weaknesses they have seen in the original “fast pyrolysis” process. Unlike the typical bio oil upgrading process using the usual catalyst, this research is not using a catalyst or hydrogen. Instead, they use in-situ generated hydrogen and supercritical alcohols to upgrade bio oil. And from this research, the research team was able to find that temperature and heat transfer characteristics are similar to medium grade oil. They believe the upgrade bio-oil from this process will generate green electricity and bio gasoline as well as, bio diesel for automobiles.